Paper pulp packaging has grown to be a Main concentration for businesses globally since they change far from unsustainable materials toward eco-helpful options. Molded pulp packaging offers a sustainable and price-productive way to provide significant-high-quality packaging that's customizable and biodegradable. one particular space driving innovation may be the introduction of higher-performance pulp molding device, such as the Dwellpac Semi-Hotpress Machine. These devices aid firms streamline manufacturing whilst guaranteeing precision and trustworthiness.This article will investigate The crucial element attributes of significant-effectiveness pulp molding machines, upkeep tips for very long-term usage, tactics to chop expenses although maximizing output, And the way automation enhances output and high-quality. no matter whether you might be a company owner or even a packaging Expert, you will obtain valuable insights to help enhance your manufacturing method.

Table of contents:

vital capabilities of large-effectiveness Pulp Molding equipment

upkeep Tips for prolonged-expression Machine functionality

Expense-Saving methods in output

How Automation Improves Output and good quality

Key capabilities of superior-effectiveness Pulp Molding equipment

large-performance pulp molding equipment are revolutionizing how molded pulp manufacturers work. The Dwellpac Semi-Hotpress equipment is a single this kind of example. It stands out for its advanced control procedure, substantial clamping precision, and seamless hydraulic effectiveness. With capabilities like precision shaping and eco-pleasant mold urgent know-how, it makes certain that every single eco-pleasant box packaging product is reliable in high-quality and sturdiness. This is significant for industries needing tailor-made solutions like food packaging, electronics, and industrial website elements. Such devices also assist a range of custom made molded pulp packaging needs, supplying sizeable flexibility in generation.

Maintenance guidelines for very long-Term device Performance

keeping a pulp molding device is vital to ensuring constant output and maximizing its lifespan. normal upkeep jobs incorporate cleansing the molding surfaces, inspecting hydraulic techniques for wear and tear, and making certain the Regulate method is up-to-date for peak overall performance. The Dwellpac machine is designed to simplify these processes, making it possible for molded pulp companies to streamline maintenance. common inspections and proactive treatment not just reduce surprising breakdowns but additionally help sustain the precision specifications needed for substantial-high quality paper pulp packaging.

Expense-conserving tactics in output

Expense-performance is a first-rate worry for molded pulp makers. To save expenditures even though retaining good quality, they're able to improve material usage by leveraging economical pulp mildew urgent technological know-how to reduce waste, invest in Vitality-economical machinery just like the Dwellpac Semi-Hotpress equipment to scale back Vitality intake, and teach personnel to fully utilize Sophisticated devices to stop faults that bring on inconsistencies or wastage. Furthermore, ordering eco-welcoming materials in bulk may help benefit from lessen charges and reduce General output prices. By adopting these procedures, brands can keep on being aggressive even though delivering substantial-good quality, tailor made eco-friendly packaging to clientele.

How Automation Improves Output and high-quality

Automation has become a pivotal facet of recent manufacturing processes. State-of-the-art pulp molding equipment makers, for example Dwellpac, integrate automation to boost operational efficiency. Automated units, by such as characteristics like intuitive Manage panels and genuine-time precision monitoring, reduce the likelihood of human problems. This makes certain that each individual mildew made satisfies strict high-quality criteria. With automation, firms may tackle significant-scale generation runs extra efficiently, meeting precise deadlines whilst making molded fiber packaging at aggressive premiums. Additionally, the dependable quality attained through automation reinforces buyer belief in eco-helpful packaging methods.

substantial-efficiency pulp molding devices are enabling enterprises to fulfill escalating demand from customers for sustainable packaging remedies. By buying State-of-the-art systems, providers can deliver tailored molded paper pulp products which not just safeguard the ecosystem but in addition give outstanding performance and durability. With revolutionary equipment and considerate maintenance practices, enterprises can get over generation troubles, lower operational costs, and offer eco-pleasant products that cater to international sustainability ambitions.

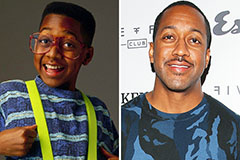

Jaleel White Then & Now!

Jaleel White Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!